Do you want to improve manufacturing processes and make operations more efficient? Are you looking for a way to increase productivity but need help with how to do so while ensuring customer satisfaction remains high? Introducing collaborative robots: the perfect solution. By integrating these automated machines into your production line, not only will you benefit from higher levels of accuracy, reliability, speed, and scalability, but you will also reduce labor costs.

In this article, you’ll explore eight significant advantages that using collaborative robots in the manufacturing setting brings to help make accurate and timely deliveries, just one part of maintaining quality control overall.

Increased Accuracy And Reliability

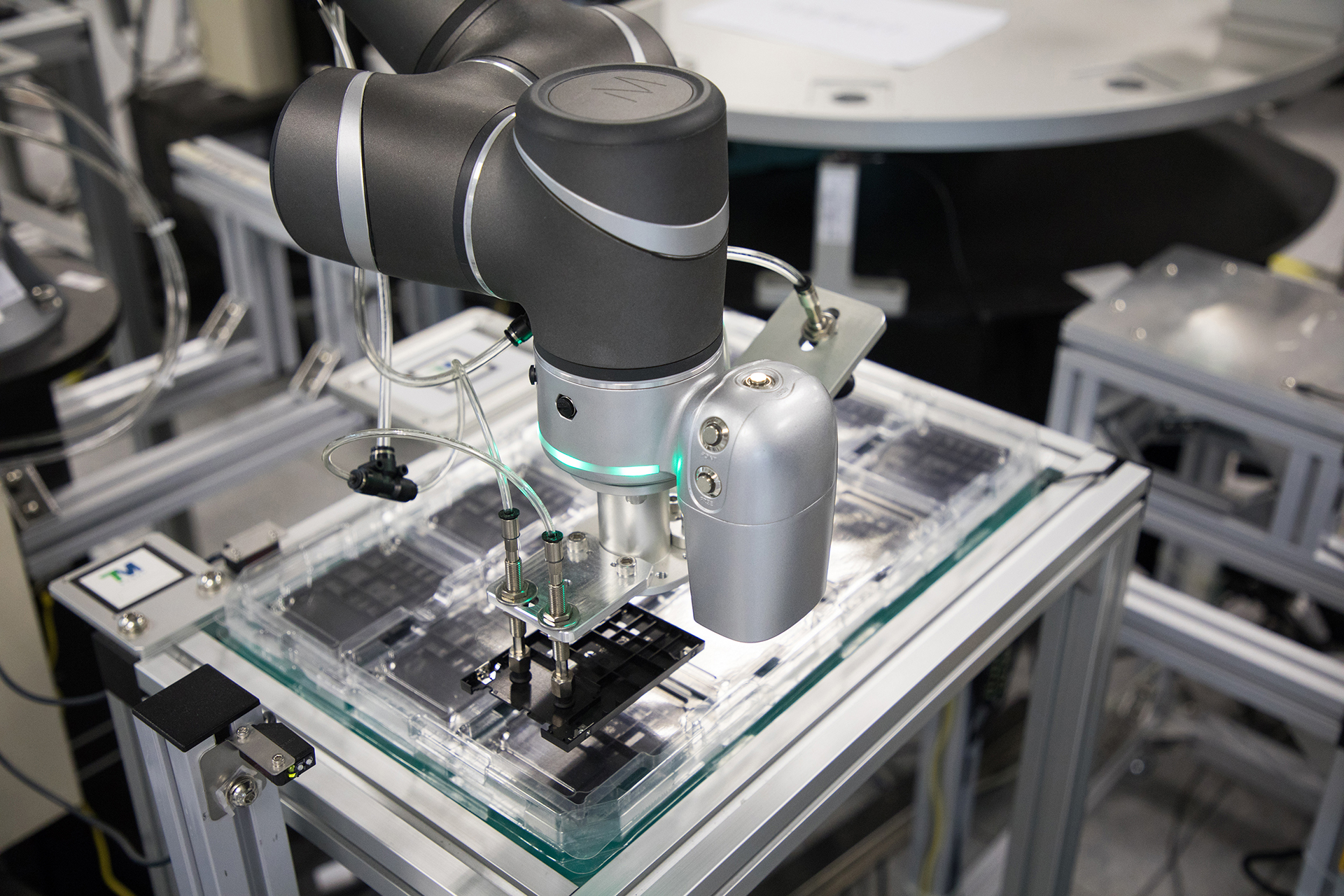

Collaborative robots possess a unique advantage in accuracy and reliability that can benefit your manufacturing facility significantly. Compared to traditional industrial robots, collaborative systems can produce parts with improved precision and more excellent repeatability by utilizing sensors and advanced algorithms that allow for intelligent self-correction.

It is crucial for businesses working in precision assembly environments that require process quality control and those dealing with extremely tight tolerances or complex micro-manufacturing applications. They can increase the overall productivity of a manufacturing plant and save significant amounts of time, materials, and labor costs.

Allowing your facility to reap the benefits of increased accuracy and reliability when introducing these state-of-the-art systems ensures maximum efficiency and cost-effectiveness over the long run.

Improved Safety

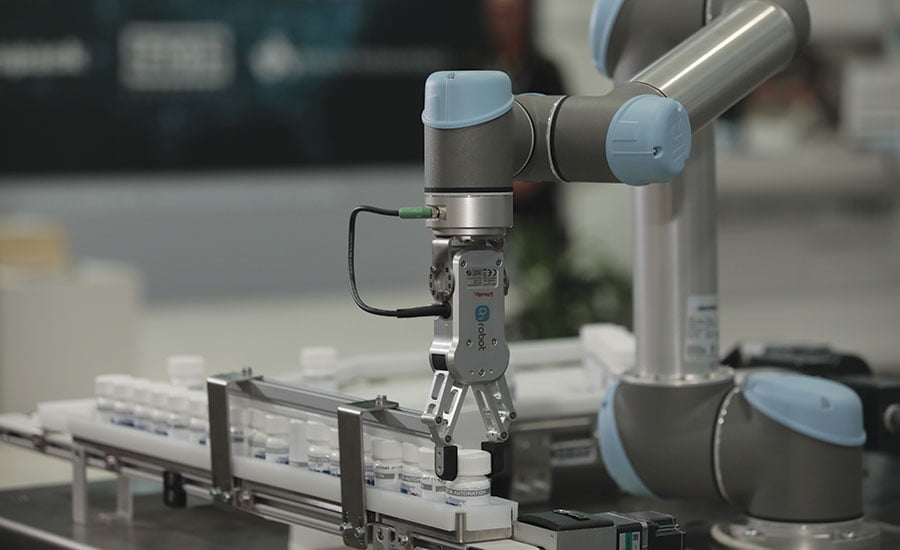

Collaborative robots are designed to work alongside human workers, making safety a priority.

These machines are programmed with safety sensors and can detect their surroundings to avoid collisions or other hazards. It makes them ideal for tasks that involve hazardous materials or require a high level of precision. Allowing robots to take on specific tasks eliminates the potential for human error and reduces the risk of injury.

In addition to physical safety, collaborative robots also help protect your facility from cyber threats by being easy to configure and integrate into existing systems. It allows you to keep your data secure while ensuring that production levels remain consistent and no confidential information is lost.

Reduced Labor Costs

One of the most significant benefits of using collaborative robots in your facility is that it reduces labor costs. You can cut back on the workforce and streamline production times without compromising quality by automating specific processes.

These machines can also work 24/7 with minimal maintenance requirements, allowing you to maximize efficiency while freeing up resources to invest in other areas of your business. It can result in cost savings that can be used to improve existing operations or invest in new technologies.

Improved Scalability

Collaborative robots are designed to work alongside human workers, making them ideal for businesses with limited resources or those looking to expand quickly and efficiently. These systems are easily scalable, allowing them to be adapted and integrated into existing production lines with minimal investment.

It makes them ideal for businesses of all sizes, allowing you to grow without reinvesting in costly equipment or increasing labor costs. Collaborative robots can also help simplify complex tasks requiring high precision levels while reducing time-consuming manual processes, providing an invaluable asset to facilities with limited resources.

Increased Speed Of Production

Collaborative robots are programmed to work quickly, delivering parts faster than traditional industrial robots or manual labor. It can significantly increase overall production speed, resulting in cost savings and improved efficiency for your facility.

The increased production speed can help you stay ahead of customer needs and ensure timely delivery. It can help you gain a competitive advantage in today’s fast-paced manufacturing environment.

Increased Flexibility

Collaborative robots are designed to be flexible and adaptable, allowing them to easily switch between tasks without compromising efficiency. It can help improve the speed and accuracy of production processes, resulting in cost savings and increased profits.

The ability to program these machines for different tasks also makes them suitable for businesses that operate across various sectors or need to quickly adjust their output in response to changing customer demands.

Enhanced Quality Control

Collaborative robots are programmed with advanced sensors to monitor parts and detect defects before they become a problem. It helps reduce waste due to faulty components or production errors, resulting in improved product quality and customer satisfaction.

In addition, collaborative robots can also be used for precision machining, resulting in higher accuracy and better overall product quality.

Improved User Experience

Collaborative robots are designed to be intuitive and easy to use, allowing workers to quickly learn how to operate them without needing extensive training. It saves time and ensures a better user experience for your employees, resulting in improved job satisfaction and morale.

By introducing collaborative robots into your facility, you can benefit from enhanced safety, cost savings, scalability, production speed, flexibility, quality control, and improved user experience. These systems provide invaluable assets that allow businesses of all sizes to remain competitive in today’s fast-paced environment while maximizing efficiency and profits. With the right robotic partner by your side, you can unlock the full potential of your production facility and take it to the next level.